Mineral processing – Milling

Practical Action

only relatively soft minerals. Small machines can have a throughput of only a few tens of kg

per hour whereas larger machines are capable of handling up to 40 or 50 tons per hour and

occasionally more. Feed size varies according to the machine. The machines are often fitted

with screens for closed-circuit grinding. Product size can be controlled by changing screens.

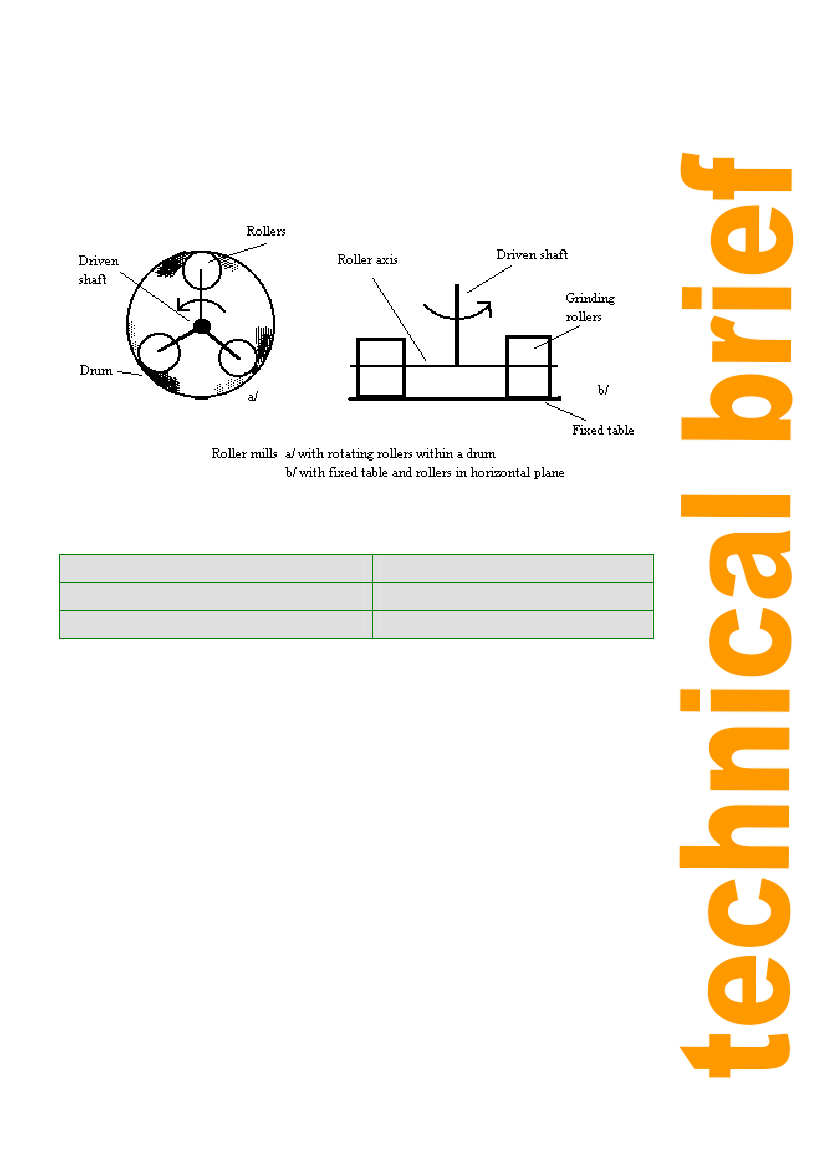

Figure 4: Types of roller mills

Barite

Limestone

Slate

Table 7: Material Suitability for Roller Mills

Phosphate

Coal

Miscellaneous chemicals

Very fine grinding mills

Hammer mills

Description:

These are high-speed mills operating at speeds of between 2000 and 6000 rpm A set of

‘hammers’ rotate about a central axis in a vertical or horizontal plane. The hammers can either

be fixed or can swing freely, in which case the mill is termed a swing-hammer mill (see figure

below). The whole system is enclosed in housing and the outlet for the product is usually via a

screen which sieves the product and allows only the required size of particle to pass.

Characteristics:

The product size can be extremely fine - talc can be reduced to a size of 0.0025mm (40%),

although an air classifier is required when such product size is required. Maximum capacity is

in the order of 10 tons per hour and power consumption is relatively high. Rotating hammer

mills are suited to the milling of softer materials and this type of mill is often used to mill

grain and other food stuffs.

7